Customer Overview

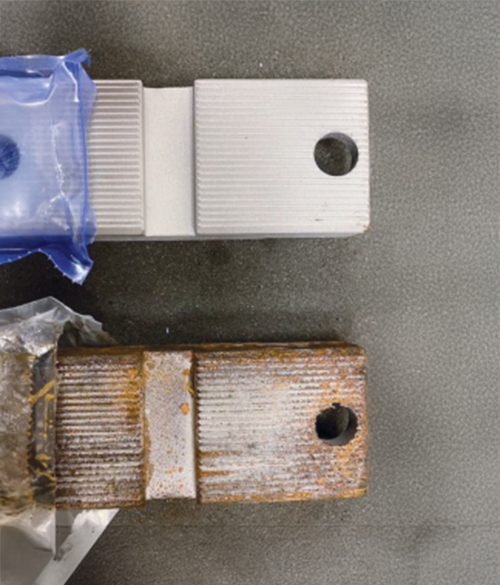

A packaging partner’s rig system required a reliable solution to protect ferrous metal surfaces – specifically cast iron grip dies – from corrosion during temporary storage and transport. NOV Upper grip dies (P/N: 10378887-001) were the focus of this evaluation.

The Challenge

Corrosion during storage or transport can lead to compromised performance and increased costs for metal components, particularly cast iron parts such as the grip dies. This necessitated an effective vapor-inhibiting solution capable of delivering superior protection under accelerated testing conditions.

Proposed Solutions

To evaluate corrosion protection efficacy, two packaging materials were tested:

- VCI2000 Blue Bag: A 5 mil volatile corrosion inhibitor bag that releases protective vapors, creating a barrier against moisture and corrosive agents. It offers advanced, non-invasive corrosion prevention and is widely used in industrial packaging.

- Polyethylene Clear Bag: A 5 mil plain polyethylene bag without corrosion-inhibiting

properties. It serves as a control, relying solely

on its physical barrier to shield items from

environmental exposure.

The comparison aims to highlight the benefits of VCI technology for industries focused on corrosion prevention.

Results

The laboratory testing followed a meticulous procedure to assess corrosion resistance. Initially, both grip dies were sealed in glass testing jars and maintained at room temperature for 24 hours. After this period, 30 mL of distilled water was added to each jar. The jars were then subjected to a 7-day cycle in an oven, alternating between two conditions: 12 hours at 95°F with 100% relative humidity and 12 hours at room temperature. This process ensured a thorough evaluation under controlled environmental fluctuations.

The testing revealed a stark contrast in performance between the two packaging materials. The grip die packed in the plain polyethylene bag showed significant corrosion, highlighting the material’s inability to protect against corrosive elements. In contrast, the grip die packed in the VCI2000 blue bag remained entirely corrosion-free, clearly demonstrating the superior protective capabilities of the vapor inhibiting material.

Want to Learn More? Connect Today!

Conclusion

The test results strongly validate the protective capabilities of the VCI2000 blue bag. By employing this volatile corrosion inhibitor material, the packaging partners rig system can significantly reduce the risk of corrosion during storage and transport, ensuring the integrity and longevity of cast iron grip dies. The VCI2000 blue bag provides a superior solution for temporary protection compared to conventional polyethylene bags.