Circularity

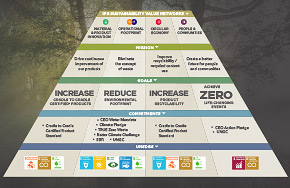

We model our SVNs after the key pillars of the Cradle to Cradle Certified Products Program, namely: Material Health, Product Circularity, Clean Air and Climate Protection, Water and Soil Stewardship, and Social Fairness. We discern the vast variety of safety and environmental certifications across the industry while working hard to ensure our products meet the high standards held under the Cradle to Cradle certification process.

Cradle To Cradle is a pioneering and globally-recognized design framework and certification developed by McDonough Braungart Design Chemistry (MBDC). MBDC is a design consultancy that works with companies of all sizes to help them create safe and sustainable products that can be cycled back into the economy through recycling or upcycling. MBDC developed Cradle To Cradle standards and certifications to give companies a framework to reference when developing new products.

Today overseen by an independent organization, The Cradle to Cradle Product Innovation Institute, Cradle to Cradle Certified products are awarded at five levels (Basic, Bronze, Silver, Gold and Platinum), with each level imposing a more rigorous set of requirements. The lowest score in any quality category establishes the product’s overall score.

Certified products include:

● Curby Mailer®

● Curby Fragile Wrap™

● Water-Activated Tape

● PaperSpace™ X-Fill™

● Acrylic Carton Sealing Tape

● Hot Melt Carton Sealing Tape

● StretchFlex® and SuperFlex® Stretch Film

● Exlfilmplus® Shrink Film

● Polyethylene Tape

● Masking Tape

● Flatback Tape

● NovaShield® Structure Membrane

● AirSpace™ Film

● Bubble Packaging

Our Approach to Sustainability

Embracing sustainability and driving change are key drivers of our business strategy. Our Sustainable Product Design and Development Vision Statement places the precautionary principle outlined in the United Nations Global Compact along with the Cradle to Cradle design principles as central pillars to guide our our aspirational transformation.

- Increase Cradle to Cradle Certified® Products

- Reduce Environmental Footprint

- Increase Product Recyclability

- Achieve Zero Life-Changing Events

Our Products

Our Commitment:

75% of packaging products manufactured by IPG, by revenue, will be recyclable, reusable, or compostable by 2025 and 100% by 2030.

-

In 2023, 66% of packaging products manufactured by IPG, by revenue, were recyclable, reusable, or compostable.

- View the Sustainability Report to see Our Actions in 2023.

Our People

Our Commitment:

Safety above all else with a goal of zero life-changing events.

-

We met our goal of realizing zero life-changing events. We completed approximately 24,700 safety contacts in 2023, up 65% from last year. The TCIR declined from 1.70 in 2022 to 1.52 in 2023.

-

We continued to cultivate environments with open communication, sharing initiatives, and engaging our stakeholders.

Our Planet – Energy

Our Commitment:

To obtain 50% of our energy from renewable sources by 2030 and reduce energy intensity by 2.5% per year.

-

We realized another slight increase in renewable energy use in 2023. Renewable energy use increased to 5.80% of our total energy use. Our energy intensity ratio increased from 5.87 in 2022, to 5.96 in 2023, a 1.5% change, due to a decrease in production which resulted in IPG missing our 2.5% reduction goal.

- View the Sustainability Report to see Our Actions in 2023.

Our Planet – Climate

Our Commitment:

Our science-based targets require a 42% decrease in Scope 1 & 2 and a 42% decrease in material Scope 3 emissions by 2030 as compared to our 2021 baseline. This aligns with our previous commitment to reduce Scope 1& 2 emissions by 50% by 2032 as part of the DOE Better Climate Challenge. Additionally, we have committed to net zero carbon by 2040 as part of The Climate Pledge.

-

In 2023, our Scope 1 emissions decreased by 22.1% and our Scope 2 market-based emissions decreased by 13.5% against our 2021 baseline, and by 20% and 6% respectively year over year. Our Scope 3 emissions last year decreased by 38.2% against the 2021 baseline, and we added additional, material Scope 3 categories for which we will report emissions going forward. Collectively, our Scope 1, Scope 2, and Scope 3 carbon emissions decreased by over 307,000 metric tons, or 23% against our 2021 baseline.

- View the Sustainability Report to see Our Actions in 2023.

Our Planet – Waste

Our Committment:

Divert at least 90% of solid nonhazardous waste headed to landfills and incineration from our manufacturing facilities to enable all manufacturing facilities to be TRUE Zero Waste Certified by 2030.

-

At the end of 2023, IPG’s diversion rate was 64%. Our facilities in Chicago, IL, Danville, VA Everetts, NC, Carrollton, TX and Truro, NS have made incredible improvement through improved data collection, internal support from management, and a broad, company-wide effort. To date, one of our facilities is True Zero Waste certified.

- View the Sustainability Report to see Our Actions in 2023.

Our Planet – Water

Our Committment:

Reduce water withdrawal by 2.5% per year and meet our commitments as signatories to the CEO Water Mandate.

-

For 2023, overall water withdrawal was down, and water use in water-stressed areas was also down. At the end of 2023, total water withdrawal decreased by 21% over 2022, while water withdrawal in water-stressed regions also decreased, even though the number of IPG locations considered to be in water-stressed areas increased.

- View the Sustainability Report to see Our Actions in 2023.