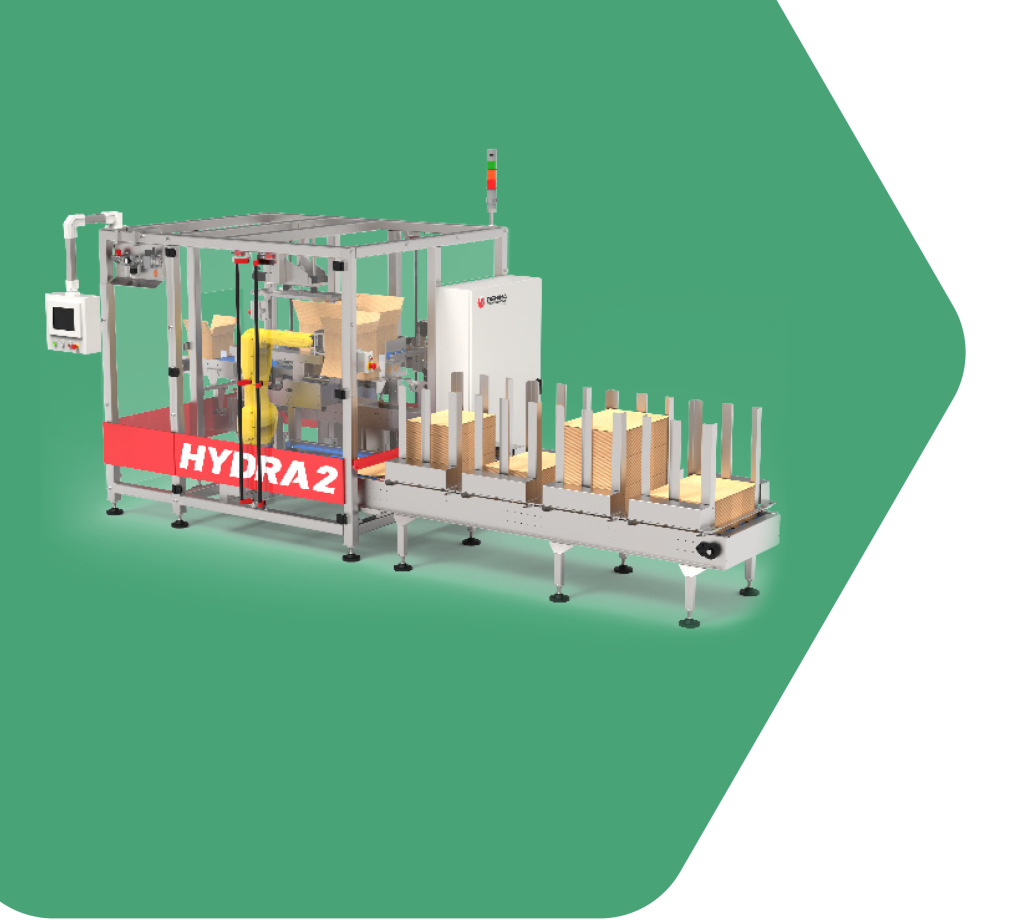

ROBOTIC CASE ERECTOR

Automatic case erector using a robot to pick and open a flat case, then transporting the case into flap folding and bottom sealing systems.

PREVENTATIVE MAINTENANCE SERVICE DETAILS

- Case Magazine(s): Check all prongs, escapements, and vacuum suction cups for wear and tear. Ensure cups seal on carton. Check case conveyor chain belt for signs of excessive wear and tear, proper tension and alignment. Check air cylinders, actuators, and confirm it functions. Check 90 deg. and 45 deg. actuators for seal leaks. Check conveyor belt sprockets for missing teeth/wear. Inspect and clean sensors/photo eye, check for proper alignment, loose connections, and wire damage. Inspect pneumatic lines and fittings for leaks. Clean as necessary. Inspect wire and cables for loose connection and cracks. Inspect motors, gearbox, and confirm no binding.

- Carton Blank Pick Station: Check vacuum cups for wear and tear. Ensure cups seal on carton. Check air wall separators for plugged ports, comb damage or cracked, secured tightly to bracket. Check timing belt for excessive wear, proper tension, and alignment. Inspect and clean sensors/photo eye, check for proper alignment, loose connections, and wire damage. Inspect wire and cables for loose connection and cracks

- Robot EOAT (End of Arm Tooling): Inspect pneumatic lines and fittings for leaks and clean as necessary. Clean vacuum generator filters. Inspect and clean sensors/photo eye, check for proper alignment, loose connections, and wire damage. Check air cylinders, actuators, and confirm function. Check pivot linkage arm for tightness, and tighten concentric cam if needed. Inspect wire and cables for loose connection and cracks. Inspect bumpers for wear.

- Gantry: Check timing belt for excessive wear, proper tension, and alignment. Inspect and clean sensors/photo eye, check for proper alignment, loose connections, and wire damage. Inspect pneumatic lines and fittings for leaks and clean as necessary. Check air cylinders, actuators, and confirm function. Check vacuum cups for wear and tear. Ensure cups seal on carton. Clean vacuum generator filters. Inspect wire and cables for loose connection and cracks. Inspect motors, gearbox, and confirm no binding.

- Closing section: Check belts for excessive wear, proper tension, and alignment. Check air cylinders, actuators, and confirm function. Inspect and clean sensors/photo eye, check for proper alignment, loose connections, and wire damage. Check tape head for proper function, tension, blade for worn edges and replace as needed. Check closing plow plates for surface damage, scratches. Inspect wire and cables for loose connection and cracks. Inspect motors, gearbox, and confirm no binding.

- Discharge conveyor: Check belt for excessive wear, proper tension, and alignment. Inspect and clean sensors/photo eye, check for proper alignment, loose connections, and wire damage. Check rollers for wear/damage, roller alignment, and ensure all rollers spin freely. Inspect wire and cables for loose connection and cracks. Inspect motors, gearbox, and confirm.

- Machine Cleaning protocol all sections

| PROGRAM SERVICE LEVEL | VISIT FREQUENCY | ADDED BENEFIT | PM RATE MULTI-YEAR DISCOUNT | PREVENTATIVE MAINTENANCE GENERAL SERVICES |

|---|---|---|---|---|

| TITANIUM | Custom frequency of your choice | Custom list price discount % on PM parts kits | Custom multi-year program discount % |

|

| PLATINUM | Monthly (12 service visits per year) |

10% off list price discount on PM parts kits |

5% – 2 years 8% – 3 years |

|

| GOLD | Quarterly (4 service visits per year) |

10% off list price discount on PM parts kits |

5% – 2 years 8% – 3 years |

|

| SILVER | Semi-Annual (2 service visits per year) |

7% off list price discount on PM parts kits |

5% – 2 years 8% – 3 years |

|

| BRONZE | Annual (1 service visit per year) |

5% off list price discount on PM parts kits |

5% – 2 years 8% – 3 years |