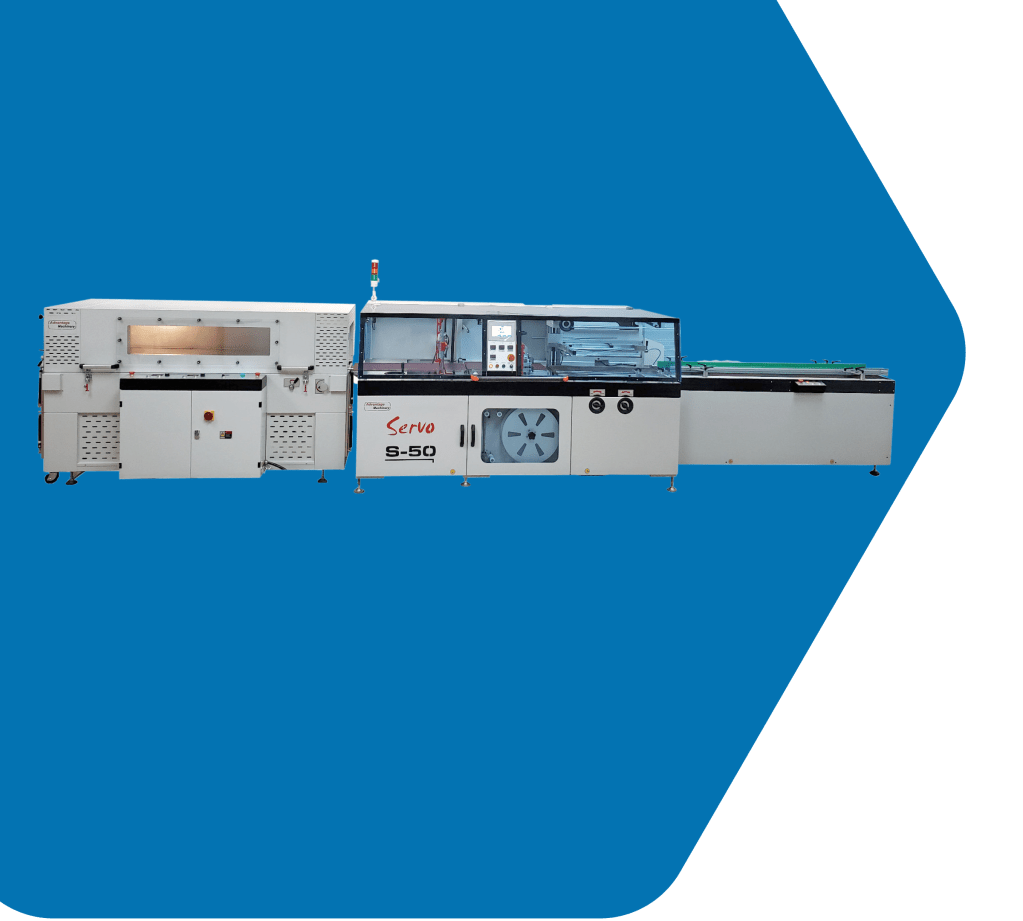

AUTO SHRINK WRAPPER & TUNNEL

Machine automatically receives product on the infeed, cuts and seals creating a shrink bag then indexing into a heated tunnel

PREVENTATIVE MAINTENANCE SERVICE DETAILS

- Shrink wrapper: Check overall cleanliness (excessive dust, leaking oil, etc.).

- Air Supply: 60-90 PSI. Check for correct air pressure based on Mfg. Specs.

- Water: Is water present and/or does it need to be emptied?

- Oil: Check for lubricant, if lubricator is provided.

- Center – Folder if Available: Check the roller’s condition and clean any excessive buildup. Check for excessive play/wear on the bushing. Clean any excessive buildup on the folding plate. Is the brake functioning properly, including any mechanical, electrical, or pneumatic parts.

- Film Unwind: Clean any excessive buildup on the drive roller and check for proper function. Is the dancer bar free floating and functioning? Check for excessive buildup and wear on the free spinning rollers. Check if the pin perf wheels are functioning, have good perf, and no slitting of film. Check for excessive wear on the perf wheel backup.

- Infeed Conveyor: Inspect the chains/sprockets/gear box for lubrication, no excessive dust, and no excessive play/wear. Are the guide rails functioning and have mounting hardware present? Check the infeed clutch for action and safety. Test the variator when the conveyor is moving if it is functioning. Check the E-Stop for proper functioning.

- Inverting Plow: Check the condition and make sure there is no excessive buildup. Check the vertical/horizontal movement for proper movement and locking.

- Control Panel: Check that all lights and buttons are working. Check the temperature controls have proper readings and function.

- Scrap Winder: Check the condition of the eagle belts and speed control. Clean as needed.

- Side Seal Assembly: Check the condition and safety features for the following: seal wire/hot bar, springs/bushings, air cylinders, cover plates, timing belts/pulleys, nip rollers, seal integrity, wire contacts, lubrication, and vertical movement.

- Side Seal Conveyor: Check the condition for the belts, rollers, bearings, sprockets, chain, and conveyor adjustment.

- End Seal Assembly: Check condition of the hot knife, blade, pad, film clamps, safeties, photo eyes, snubber cylinder, brake, horizontal movement, shafts/bearings(H), vertical movement, shafts/bearings(V), end seal cylinder, and crank assam. encoder (Tooth Ctr).

- Discharge Belts: Check the condition.

- Transition Rollers: Check the condition when present and free spinning.

- Shrink Tunnel: Check the conveyor belt’s condition as well as the tracking, conveyor lifter rod, air return vents, and air flow controls. Assure there is proper control over the temperature, air flow, conveyor speed,and blower motor.

| PROGRAM SERVICE LEVEL | VISIT FREQUENCY | ADDED BENEFIT | PM RATE MULTI-YEAR DISCOUNT | PREVENTATIVE MAINTENANCE GENERAL SERVICES |

|---|---|---|---|---|

| TITANIUM | Custom frequency of your choice | Custom list price discount % on PM parts kits | Custom multi-year program discount % |

|

| PLATINUM | Monthly (12 service visits per year) |

10% off list price discount on PM parts kits |

5% – 2 years 8% – 3 years |

|

| GOLD | Quarterly (4 service visits per year) |

10% off list price discount on PM parts kits |

5% – 2 years 8% – 3 years |

|

| SILVER | Semi-Annual (2 service visits per year) |

7% off list price discount on PM parts kits |

5% – 2 years 8% – 3 years |

|

| BRONZE | Annual (1 service visit per year) |

5% off list price discount on PM parts kits |

5% – 2 years 8% – 3 years |